Abstract

Additive manufacturing enables industries with a new production typology. For the metal manufacturing industry, this new means of production extends the spectrum of achievable building parts that can be fabricated and integrated into architectural designs. Consequently, this process is becoming increasingly relevant for construction industries. The application of additive manufacturing in metal fabrication industries requires high performance technology and extensive knowledge of material and process. Within this paper, we focus on the implementation of incremental point welding as a metal additive arc welding strategy. The goal is the realization and optimization of a manufacturing method which implements adaptive strategies in the control of this production process. In this research, incremental point welding is used for the production of branching structures. Incremental point welding is a type of metal arc additive manufacturing which deposits material by adding individual welding points rather than layering welding seams. This process is interesting for a number of reasons. The incremental application of individual metal drops simplifies the analysis and forecast of residual stress and temperature developments. Consistent arc initialization within point welding is hard to control and, therefore, requires further exploration. This led to the following research in developing an adaptive process. Furthermore, the potential of the process is increased by the possibility of tool-path adaptivity for a robotic system enabling the robot to produce welds at complex approach angles. This research developed a novel approach, able to manufacture complex branching structures while compensating for inaccuracies caused by the welding process using image processing and an adaptive strategy. First experiments showed the possibility to work at a range of overhang angle in addition to multiple approach angles up to 50°. This adaptive process increases the potential application of this technology for the extensions of existing structures as well as repair of metal structures through incremental point welding.

Similar content being viewed by others

1 Introduction

Additive metal manufacturing and incremental point welding as well as brief overview about adaptive robot control in manufacturing are introduced in the following section.

1.1 Additive manufacturing in metal

Additive manufacturing in metal has attracted a large amount of interest in manufacturing industries over the last years. This process has the potential to offer lower production costs for small lot sizes, to be more cost effective in producing work pieces which require high removal rates, and to provide more flexibility in producing challenging design geometries (Coykendall et al. 2014). This process allows manufacturers to fabricate complex structures such as lightweight and structurally optimized parts that would be cost prohibitive to produce by traditional methods. This also enables the direct fabrication of assemblies which previously required a number of subcomponents (Cotteleer and Joyce 2014). To realize additive manufacturing in metal, a multitude of strategies and techniques has been developed. The main requirements of these techniques can be considered in reference to cost, efficiency, technical complexity, production speed, material, and structural performance of the result.

Existing additive manufacturing processes can in general be classified in seven major groups: binder jetting, directed energy depositing, powder bed fusion, material extrusion, material jetting, sheet lamination, and vat photo polymerization (Malladi 2017). Within metal fabrication, the most commonly used techniques are selective laser melting and electron beam melting, which both are powder bed fusion methods (Biffi and Tuissi 2017).

These techniques have a high resolution with layer heights of less than 50 µm, allowing for an extremely high precision of product to be realized. Furthermore, the differences in the workflows for variable materials are comparatively small. The main disadvantages are the high cost, the significant technical knowledge required, and the limited build volume contained within the machines enclosed space. These current constraints make it challenging to create large-scale structures or fabricate directly onto existing metalwork. For architecture scale fabrication or onsite additive manufacturing, a process is required that is robust, cost effective, and not constrained to small-scale production. For these reasons, metal additive arc welding is a process with high potential for application in the AEC industry.

1.2 Incremental welding as an additive manufacturing strategy: state of the art

Within metal fabrication, typically additive manufacturing systems can be generalized into three components: A power supply, a wire feed unit and a motion system. These components are also provided by welding systems, a much more established method in metal fabrication. Typically welding is used for structural joining of steel components. The automation of welding using robotic systems has been widely established in the metal fabrication industry. This technique is now being developed for 3D-printing purposes. The use of an arc welder as a power source and welding wire as feedstock has been investigated since the 1990s. This process is called Wire Additive Arc Manufacturing (WAAM) (Acheson 1990) a term coined by Williams et al. (2016).

The motion system can be either a robotic system or a computer numerical controlled gantry. However, the WAAM hardware uses mainly welding equipment, which allows for large-scale production, onsite fabrication, and comparatively low costs for wire material and setup. Gas metal arc welding (GMAW) has been established as a process for material deposition due to its comparable high deposition rates. In particular, controlled short circuiting processes such as cold metal transfer (CMT®) from welding manufacturer Fronius, Synchrofeed® from OTC, or ColdArc® from EWM are often applied. These processes excel in controlled wire deposition with reduced heat input. The biggest advantages of WAAM are decreased limitations in part size and the relative low-tech setup resulting in an open architecture and low capital costs. As has been noted, WAAM processes are best suited for the fabrication of medium- and large-scale components (Williams et al. 2016). One challenge of this approach is the residual stress associated with the shrinkage during cooling and the resulting impact on structural integrity (Ding et al. 2011; Colegrove et al. 2014) as initially described by Williams et al. (2016). To use finite-element methods to model the resulting shrinkage and residual stress is especially difficult because of the geometric influences on the heat flow and the large amount of process parameters that affect the resulting structure.

1.3 Incremental point welding

Incremental point welding is a variation of the WAAM approach where instead of producing structures by continuous welds, point welding is used to add material. The process is similar to the WAAM approach in its use of GMAW welding as additive manufacturing method. Based on the point or single metal drop as base geometry, this process especially suites the needs for the fabrication of line and branch structures, where welding a continuous line is not possible. Such structures currently have to be manufactured from multiple subcomponents or cast making individual fabrication extremely expensive.

Incremental point welding is an interesting research topic due to two aspects of the process. First, it focuses on the beginning of the welding process. This moment where the arc is ignited is less explored than the welding of a continuous seam and the point weld is often unstable. A greater understanding and control of this part of the welding process could be extended to other WAAM methods, thereby contributing to the overall advancement of the field.

Second, the use of only point welds makes the analysis of the heat flow and the resulting residual stress easier, because a drop/sphere-shaped heat source model can be applied. Pertaining to process control, incremental point welding offers an important simplification. Due to the consistent duration of the start and end of each welding point, the regulation of the welding process is easier than the regulation during a running weld seam.

1.4 Adaptive robot control

Most industrial robotic processes utilize linear workflows. This process begins with a design and its representation in 3D space. The robotic tool-path planning is derived from this digital product model, including the integration of additional tools such as welder power sources. The robotic path is translated into machine code which controls the execution of the robot process (Snooks and Jahn 2016).

These linear (non-recursive) workflows are the most common way of robotic control. However, the idea of integrating sensors and adaptation into process is nearly as old as the integration of the first robots in industry in the 1960s (Hong et al. 2014).

The concept of adaptive workflows is to advance from linear to recursive workflows, where processes are constantly measured to dynamically inform following actions. This concept utilizes a robot to actuate, sensors to interpret processes and a computer to calculate the next appropriate robotic action.

For many years, sensing systems have been an indispensable tool in steel automation, used to improve processes and ensure arc welding quality (Hong et al. 2014). While the robotic welding industry already utilizes adaptive systems, such as sensor driven seam tracking, and arc voltage monitoring, there are still many areas left for research. As processes grow more complex, it becomes necessary to advance the adaptive capabilities of robots beyond current industrially available solutions. This is necessary to deal with the growing demand for automation solutions capable of adapting dynamically to changing processes, materials, factory environments, and onsite conditions.

Within the field of adaptive robotics, there are a range of approaches from projects such as: towards visual feedback loops for robot-controlled additive manufacturing, where the robot programming reacts adaptively to unpredictable material and environment (Sutjipto et al. 2019) to more general changes in the fabrication paradigm. The project: on the relationship of multi-agent algorithms and robotic fabrication is such an example, where the robot is used as a design agent more as just a tool (Snooks and Jahn 2016).

A key aspect of achieving adaptivity in these projects is the integration of sensors.

Visual sensors are often used in assembly to categorize non-prefabricated parts as shown in designing natural wood log structures with stochastic assembly and deep learning (Wu and Kilian 2019). However, visual sensors are not often used in additive manufacturing to react to non-predictable material behavior and environmental influences (Snooks and Jahn 2016; Sutjipto et al. 2019).

As the ability of robotic path planning systems has become more accessible the ability to integrate different sensing systems into an adaptive process becomes more powerful in its impact. This impact grows even more influential as the latest developments in image processing and convolutional neuronal networks allow computers to tackle ever more complex problems.

2 Experimental setup and method

2.1 General process

In the following passage, the setup and the methodology as well as the experiments are described from general to explicit on the one hand and in order of the most important steps of development on the other hand.

For the realization of incremental point welding, a basic setup was used consisting of a 6-axis, KUKA KR-16 robotic arm with a welding torch (Abicor Binzel) mounted as a robotic end effector for material application. The welding torch connected to the welding power source EWM alpha Q 551 pulse was mounted as end effector to the KR16 and controlled separately from the robot (Fig. 1).

As a material, a standard non-copper-clad steel wire G3Si1 was used and combined with an 8% CO2 and 92% argon-shielding gas mix. To simplify the process and reduce the amount of parameters, the arc time was set to 500 ms and an approximated cooling time of 1.5 s was assumed.

The programming of the robot’s toolpath was developed in Grasshopper3d (a visual programming environment for Rhino3d CAD software by McNeel). To connect the programming environment with the robot, KUKA|prc was used in combination with the KUKA MxAutomation Interface, an interface provided by KUKA to allow the transfer of programs to the controller via a Programmable Logic Controller (PLC). KUKA|prc is a Grasshopper3d plug-in created by Association for Robots in Architecture implementing parametric robot programming and accurate real-time simulation (Braumann and Brell-Cokcan 2012). It was further extended with a virtual PLC in order to directly connect with the MxAutomation Interface (Braumann and Brell-Cockan 2015).

Within the experimental setup, the welding power source is controlled separately using LabVIEW and not connected directly to the robot controller. This separate controller system was, therefore, connected through an UDP socket, establishing a connection between LabVIEW and Grasshopper. To synchronize between the robotic movement and the triggering of the welding torch a constant position checking between the actual robot position and the next welding position was implemented. This was accomplished by analyzing the position feedback of MxAutomation within KUKA|prc. Although this added additional synchronization complexity to the process planning, it allowed for the differentiation between process and geometric parameters, as well as the overlay of both models. This in turn led to the following welding point workflow: If a matching position is detected, then a signal will be sent over LabVIEW to the welding control and the arc will be ignited with the set arc time of 500 ms.

2.2 Phase 1: static process

2.2.1 Setup

The first approach was a static process (without adaptation) using the described basic setup. For the first experiment, the input was a simple curve geometry approximating a helix. The generation of the toolpath was realized using a division distance of 0.6 mm which was determined using empiric methods for an arc time of 500 ms (ms) and a wire speed of 2 mm/s.

2.2.2 Method

To convert the input into an executable toolpath, the curve geometry was divided by the determined division distance of 0.6 mm between each welding point. To determine the process angle, the curve normal at each welding point was taken to create the tool-path plane. The 6-axis system of the robot supports this approach, so that it is possible to have similar base conditions for each welding point. The micro-toolpath for each point consists of five major steps. An approach in normal direction of the plane, a 500 ms wait, while the arc is burning, the welding point itself, a 1500 ms wait after the welding process for cooling and a departure in normal direction. In between the welding points, the robot moves in a linear motion to avoid collisions with the printed structure. The analysis tool of KUKA|prc was used to check if it is possible to fabricate the geometry based on the robot’s kinematic constraints which moved the focus towards process adaptivity. For the initial experiments, a pulsed GMAW process was employed with an average 18.0 V voltage and an average amperage of 67 A at a wire feeding rate of 1.8 m/min. With the instant position, checking the welding process was ignited, whenever the robot reaches a welding position. After the cooling time, the robot moved to the next position. Due to the complexity of the welding process, the weld often failed making a high amount of observation and manual modification necessary. If the process ran into a problem, the robot was paused and the welding power source was toggled manually to add missed welds or close gaps in the structure.

2.2.3 Result

This leads to two main research focus areas for increasing efficiency; how to maximize accuracy, and how to increase process speed.

Inaccuracy in the process had a large influence on the efficiency as this required the operator to stop the robot and to manually adjust the structure or the process. To achieve an efficient speed also required the optimization of the cooling period between point welds. A cooling time of more than 2 s per point was determined to be an unacceptable amount of time when the high number of welding points for complex structures was taken into account. The simple helix experiment (Fig. 2) with over 300 welding points took more than 5 h which highlights the importance of fabrication efficiency in this process. In most welding-based additive manufacturing methods, the cooling time is a key driver of the process efficiency (Mueller et al. 2014). The critical influence of the cooling period appears clearly with in the printing process of this single curve structure. Because it was printed drop by drop, the cooling had to be implemented as interruption of the process different from the regular WAAM approach, where cooling happens with in the continues process, while the actual layer is finished.

However, the process of printing point by point allows the printing of multi-curve structures to continue at another part of the structure while cooling the previous part thereby making the overall build-up process faster.

To speed up the process, the geometry had to be sliced layer by layer to decrease the mean time between fabrication steps.

Even more important was the influence of the inaccuracy caused by the fact that welding is a complex process depending on a high amount of different parameters with complex constraints. With a non-adaptive approach, this led to unpredictable process results such as the non-uniform addition of material and the resulting inaccurate effect on the structures buildup.

The inaccuracy of inconsistent buildup was a problem as the distance between the welding torch and the structure was not consistent with the digital model. This caused the shielding gas coverage to be inadequate allowing environmental contaminants into the weld and ruining the quality of the structure. The inaccurate distance between torch and structure also impacts the welding process due to the inconsistent voltage running through the filler metal. The inaccuracies accumulated with each welding step leading to a recursive error system and an unpredictable buildup of structure (Fig. 3). The unpredictable distance between welding torch and structure causes process instabilities, as this prevented the arc from igniting for the necessary amount of time to deposit the desired amount of metal to the structure. Atmosphere gas was reacting with the weld caused by a weak shielding gas cover and was leading to collapsing pores caused by nitrogen in the air and extended burn-off. The re-ignition was then interrupted by the oxide layer.

To continue the project, the accuracy had to be improved both to create useful and reliable results and to be able to manufacture more complex geometries. Two approaches were developed to achieve this: detailed parameter testing and the implementation of adaptive strategies. The first generic approach involved detailed parameter testing to find a fitting set of parameters for a good working process. The disadvantage of this approach was mostly caused by the high amount and the complexity of parameters influencing the welding process. This is significant as the geometry also has a high influence which means that a detailed parameter testing for each new geometry would have been necessary. The second approach was the implementation of adaptive strategies for process control correcting the next weld based on the last one.

2.3 Phase 2: adaptive process

2.3.1 Setup

Consequently, and based on the results of the static process, the control of the distance between the welding torch and structure was determined to be the most important goal to achieve. To analyze this distance and the structures growth, image processing was used to determine the position of the welder relative to the last welding point.

For this, the camera setup developed by the group of process controlling and monitoring at the ISF (Welding and Joining Institute at the RWTH Aachen University) was used. The Photonfocus HDR camera-type HD1-D1312-80G2 was chosen for monitoring and control of metal arc-welding processes. The basic setup consists of the HDR Camera mounted under the welding torch (Fig. 4) and connected to the interface computer by a gigabit Ethernet (GigE) Vision link. The GigE Vision protocol is also used to configure the camera before and during operation.

The computer vision based image processing was implemented using the NI Vision Development Module offered by LabVIEW for industrial vision application. The collected data are passed to Grasshopper3d using a UDP socket. These image data were then utilized to inform the feedback loop. The adaptive process control was realized in Grasshopper3d. However, as Grasshopper3d was developed as an algorithmic programming tool for parametric workflows, it caters only for a-cyclic graph structures. Data streams that loop are not inherently possible without further software extensions (Tedeschi and Wirz 2014). This presented a problem for the MAAW adaptive process. To implement the adaptive feedback loop.

It was necessary to program the loop logic as an internal component whose recalculation was triggered by the continuous feedback of MxAutomation. To control the fabrication out of this loop, the override speed of the robot was changed through the created internal component. This allowed for the temporary pausing of the robotic process to fire additional welds if necessary without canceling the program.

2.3.2 Method

A new slicing method was employed to speed up the fabrication process. Instead of dividing the curve geometry by a specified distance, the geometry was divided by a set of generated planes with a specified distance oriented to the main build-surface. This allowed the robot to move to the next welding point, while the previous point cooled. Utilizing this method, the non-value added wait time of the robot was more efficiently used to create additional points.

As a next step in improving the incremental point welding, the adaptive process control logic of the feedback loop was implemented. The aim of the feedback loop was to determine if the amount of material added was enough to fill the digitally planned gap between welding positions (Fig. 4).

This in-process quality control method allowed for the constant monitoring of the distance between the end of the welding torch and the build-up structure. After the welding power source was triggered and the welding arc ignited, a picture was taken by the integrated camera and sent to LabVIEW. The distance was analyzed using computer vision libraries and the interpreted data were fed back to the control loop. This led to the following process logic: if the distance was as hypothesized, then the process was continued as planned. However, if the distance was too large, the robot speed was set to 0, effectively stopping the robot. At this point, with the robot in the same position, the welding power source was triggered again.

This additional weld would slightly close the distance between torch and structure.

Since the welding arc was only ignited again at the same position, it is important that the robot was held in position and prevented from moving in the cooling time if the weld had failed. For this, the override speed of the system was set to zero by the algorithm if the returned pixel distance was larger than the maximum and set to the original value afterwards.

This in-process quality control method would be repeated until the proper distance was achieved. If the weld ended up too close to the torch, the cameras would detect this and the following points of the geometry were moved to by the robot, but the welder was not fired. These process logics allowed the robot cell to adapt to either condition (too much weld or too little) with appropriate actions to maintain the welds quality.

To get the distance from the computer vision process, two assumptions were elementary. First, it is certain that the position of the welding torch in the captured image is a constant distance from the camera. This constant allowed for the determination of the distance of the point weld from the camera using static pixel values. Second, the welding edge can be found by evaluating the brightest contour in a mono-chromic picture. This edge can then be used to calculate the weld center point. To validate the second assumption, the timing of the photo was fundamental. If the picture was taken too early, then the bright light of the arc would disrupt the calculation of the correct result, while if the picture was taken too late, the heat and the brightness of the welding point were not adequate for the illumination of the picture.

The computer vision consisted of four major steps. Step 1 applied a threshold which was used to convert the image into to a binary picture. Step 2 determined the largest contour of the weld. In step 3, the center of the weld was analyzed. In step 4, the distance between the torch and the centroid is calculated through the pixel value. This value could be converted to an absolute distance, but for the monitoring of the change, this was not necessary. In determining the accuracy of the weld buildup, the relative change between the current and the previous value was more important than the absolute distance. Furthermore, in a consistently used setup, the borders for a successful weld could be defined in pixel values without converting them into absolute distance. The borders for this pixel values were determined experimentally to consist of a minimum of 60 px and a maximum of 400 px. Such values were determined using the robot approach normal, the geometry to be constructed curve, and the described welding parameters.

For the implementation of the adaptive strategy, the in-process quality control method and the new slicing approach were combined. This adaptive method was used to create a more automated process that required less manual monitoring and intervention and produced more consistent results (Fig. 5). The enabled the research to proceed with developing an understanding of the impact geometries has on the robotic additive process.

First experiments included investigations of the overhanging behavior, the approach angle, and the behavior of branching and connecting. These were realized using the implemented in-process quality control method. Based on the small amount of test objects the evidence of the experiments is more qualitative then quantitative.

To get an idea of the overhanging behavior of this process, a small experiment testing angle between 0° and 45° was made. Three linear geometries with 30 mm length were weld in an angle of 0°, 30°, and 45° with no significant error showing based on the different overhanging angles.

In a second experiment, different approach angles were tested. The approach angle is derived relative to the normal of the curve. In this experiment 5, straight linear geometries with a height of 50 mm were fabricated. The first 20 mm were fabricated with a normal approach after this the structure was fabricated with an approach angle of 10°, 30°, 50°, 70°, and 90° (Fig. 6). The fabrication of the three first approach angles was successful with no major problems, but the fabrication with an approach of 70° or 90° failed.

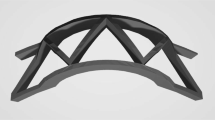

In a third experiment, the possibilities of dividing branches or connecting them were investigated. Therefore, a complex structure was fabricated integrating the division of one branch in 2 and 4 different branches and combining 3 and 4 branches to one (Fig. 7).

2.3.3 Result

Throughout the experiments, each welding point was analyzed and executed through the implemented adaptive process control. While the in-process quality control monitors the distance between the torch and the intended weld point, it should be noted that each correction point, being welded from the same robotic position, deviates slightly from the intended geometry. These deviations are minor, since the process monitors each weld and corrects with few additional welds. The adaptation monitors the distance while allowing adaptivity in a very local range to accomplish the fabrication task within a set tolerance. This is referred to as “local” adaptivity related to the constrained reach of its influence. The process adaptivity was simplified to the decision as to triggering or not triggering of the power source. The robot was only controlled adaptively using the override speed to stop the robot and let it stay in position while reigniting the welding arc. This is local adaptivity. In contrast, a global strategy would consist of modifying a larger scope of the process including, the toolpath, the welding positions, or even the geometry of the finished structure. This larger adaptive capability is referred to as “global” adaptivity.

A first concept of the process constraints and relationships was established by these first experiments. The overhanging behavior was different than expected in contrast to common 3D-printing and it was possible to print with a 90° overhang without any correction necessarily needed. Even though the effect was less intense than predicted, the gravity-based effects were determined to be dependent on the angle and on the cooling time—the longer the cooling time the higher was the viscosity of the metal drop and the smaller was the effect.

The results of the second experiment exceeded expectations and showed that the structure was able to be fabricated even with an approach angle of up to 50°. The abrupt change of the approach angle showed the deviation of the actual height to the hypothesized height as a small offset in the linear structure (Fig. 8). The larger the approach angle gets the more material gets lost due to the reduced protection of the weld with the shielding gas, leading to porosity, burned metal, or dispersion/spray of liquid metal. This results in a need of more welding positions for parts with larger approach angles. Through such experiments, it was clear that the approach angle was an important process parameter that could be adjusted to obtain a quality structure.

The third experiment showed that the dividing as well as the connecting of branches is possible for the fabrication process and the adaptive process control (Fig. 9). A closer look to the input curve geometry showed that there are duplicate point and welding positions at the connecting or branching points. Without adaptive monitoring of the process, this would have led to a faster buildup of the structure and a possible collision with the welding torch during robotic movement.

Apart from the process parameters and problems specific to incremental point welding, such as timing, interaction with the six-axis system, and the use as 3D-printing method, the process was interrupted by problems known in common welding applications. Challenges included silica forming on the weld surface inhibiting subsequent sparking of the welding process. At times, the process was interrupted by the wire getting stuck to the structure during the welding process. When this happened, the robot would move the base object out of its calibrated position or the robot would trigger a safety stop.

The interruption of the process by silica forming was a problem that occurred with a high frequency. As the power source could not ignite the next arc, the power source was triggered again, but because of the silica forming, no arc could be ignited. This problem was mediated manually, but could in future work be detected by employing the welders integrated electrical sensor system to analyze if the welding circuit is closed to automate this quality control.

The second problem, where during the weld, the wire would end up stuck to the object was caused by a delayed ignition of the power source with the resulting arc very small and the wire was welded on the structure was important to manage not because while it happened infrequently, it would lead to not only interrupt, but cancel the whole fabrication process.

The detachment of the wire after welding, therefore, needed to be verified within the process control. This was achieved by triggering another current curve to detach the wire before continuing the process. This detachment detection can also be realized using the test current of the welder and, therefore, automated, though this was not undertaken during the scope of this research. An effect of the adaptive process control was that the relationship between geometry, process parameters, and the fabrication results was difficult to discern when trying to understand cause of failure. Often, it was not possible to pinpoint which parameter was causing which problem. The investigation of the relationships between geometry and process parameters of incremental point welding was made more difficult without a means to visualize, capture, and communicate the actual adaptive fabrication process.

Consequently, further investigations into process capture were required, as discussed in the following section.

2.4 Phase 3: real-time process capture

2.4.1 Method

The ability to link causes to specific effects was enabled by capturing the in-process quality control method data. The controlling algorithm would, in real-time, export relevant data to both the adaptive process and to a log file for visualization and post-analysis (Fig. 10). Within the following section, the timespan of 500 ms is considered as the real-time cycle of the in-process quality control method including one arc execution and interaction of the algorithm with the robot and the camera. This definition assumes that the relevant parts of the process to monitor are the welding point and the adaptive decision-making process. This time measurement does not include the intermediate movements of the robot. After the process, it should be possible to create a three dimensional model of the structure and understand the decision making of the algorithm. The following information was logged for this purpose:

-

the index or rather the position of the point within the program

-

the points target coordinates

-

the number of times the arc was ignited or if it was skipped

-

the progress of the structure

-

the process duration until this point

Furthermore, the date, the number of points, and the approximated weld duration were written at the beginning of the file. With every iteration, these data were added to the file to complete the process capturing. The connection with the images and the welding points was further annotated with information regarding the welding point index, so that quality investigations could link decision data to image date to weld position in the structure. This inline documentation and reinforced model allow the user to investigate areas of the final structure, where deviations occurred to assess the structural result. These data could be used to also determine, where user maintenance was required to understand how much operator monitoring was required.

For instance, the process interruptions by silica forming were improved by the implementation of an automated pausing of the process after a certain number of triggered welds at the same position failed to ignite an arc.

The silica forming was not prevented, but the process handling for the operator was improved exceedingly. The robot would wait until the operator could assist its operation by cleaning the weld surface and cutting the excess weld wire. Even though the individual process issues were not solved, the possibility for manual interaction was automatically implemented allowing the process to attempt complex experiments without the need to physically monitor each robotic interaction for error. The quality of human interaction required could be analyzed through the visualization of the robotic process. While the spheres in these images represent a weld point, the color represented the number of times the power source trigged in this position. Any red spheres would indicate operator maintenance or interaction. The connection between adaptive process and data visualization enables the development and optimization of incremental point welding processes in steel.

2.4.2 Result

Typical workflows in automation use digital geometry to derive robotic toolpaths and movements. This research goes further to re-inform the digital model with production process information. This tool helped with an understanding of how to optimize parameters after each prototyping process.

Two major aspects were analyzed and optimized using the visualization of the real-time captured data. First, the chosen geometric parameters of the design such as the angle of the branches or position and design of the branches’ connections could be evaluated by the use of the captured data. The real-time capturing restored the link between cause and effect of process results, design, and production parameters. Therefore, real-time capturing made the process setup with adaptive process control beneficial for parameter testing, too.

Second, the implicit feedback loop between design and production was used to optimize the slicing distance. A continuing repetition of skipped welds was an indicator in the captured data that a better division distance would be ideal. The fabrication process was continuously optimized based on the captured image data. Future research would look to further automate such global adaptivity into the adaptive incremental point welding process.

3 Conclusion

In this research incremental point, welding was implemented as an additive manufacturing strategy based on the WAAM approach and extend with adaptive process control and data visualization. The extension of the static process was necessary due to an unacceptable level of accuracy and high level of user time and interaction required to maintain the process. These inefficiencies reduced the geometric reliability of the result and the effectiveness of important welding parameters such as the distance between the welding torch and the structure.

This inaccuracy was largely caused by unpredictable material deposition, resulting in a self-reinforcing/recursive error in the system until failure. To get better control, the adaptive process control was implemented instead of extensive parameter testing. This approach was considered more effective in light of the high amount and complex interaction of the welding parameter space. This adaptive method also had more potential to transfer to other setups and systems in comparison with extensive parameter testing for each individual robotic cell.

To analyze the process and material deposition, image processing was used to determine the changing distance between welding torch and structure after each welding point. This allowed an adaptive control using the welding power source to adjust the material deposit by re-triggering the weld or skipping the next one. This local adaptivity does not directly change the toolpath, but adapts the robotic process using the override speed to pause the robot in position while adapting the firing of the welding power source to compensate for inaccuracy.

In combination with a layer-based slicing and a real-time process data, capturing the print speed was improved and first experiments referring to the geometric-based process properties were made. The resulting additive process especially suites the fabrication of curve-based line and branched morphologies with complex geometry or knots combining multiple branches.

4 Outlook

4.1 Complex slicing

The results show the necessity for development in different parts of the process such as slicing, adaptivity, and robotic approach to develop incremental point welding into a more efficient additive manufacturing strategy.

Further research and the fabrication of more complex geometries will require a new slicing strategy. Neither the curve distance nor the layer slicing strategy will solve for curves which are near to parallel with the fabrication base plane. In this case, the curve distance-based slicing strategy will result in unnecessary long waiting times, while cooling and collisions and the layer slicing generate too few welding points. In the worst case scenario, if the curve is perfectly parallel, it is possible that the slicing strategy returns no welding points.

To avoid these problems, a slicing strategy based on the combination of both curve distance and distance from base would have to be implemented. This new slicing algorithm could contain three basic steps. The first step is to divide the input curve geometry with the given welding point distance. Then, based on the distance to the slicing planes, the points are sorted. Each generated point has three aspects of information, the layer, the curve, and the index on the curve. In the last step,the point order is optimized to guarantee that the points will be welded in an appropriate sequence, layer by layer integrating the point with the smaller index of curve before the next index. This approach could also provide the chance to optimize the toolpath, so that no cooling time is needed, but the amount of robot movement is as small as possible.

4.2 “Global” adaptivity

The implemented adaptivity strategy was described as “local” adaptivity related to the reach of the influence and the fact every point is analyzed as an isolated process. This “local” adaptivity has a number of disadvantages making it necessary to think about an implementation of a more “global” adaptive strategy not only triggering the welding power source again, but modifying the toolpath and welding distances directly.

The major problems of the “local” adaptivity consist in the inefficient way of skipping welding points and the necessity for the robot to wait in position if a welding point failed. This is a non-value added task which causes a longer fabrication time than necessary.

In addition, the current implementation of MxAutomation within KUKA|prc does not allow for full modification of the program during execution. Furthermore, the integration of an adaptive strategy that allows the modification of the robotic movement would offer more possibilities for problem solving in difficult cases. This would for example allow to react to silica forming with an automated cleaning process initiated by the robot.

The challenges of this step will be to develop certain strategies for implementing a reliable collision checking process and automated detection of collisions and problems caused by the kinematic constraints such as reachability and singularities. It will be hard to react on the adaptive changes in the toolpath in real time, because the number of potential collisions grows with each fabrication step in additive manufacturing. That means that the environment and the robot have to be checked continuously, but the growing structure has to be simulated and checked as well.

Another aspect of a global adaptivity approach requiring future development would integrate management of the geometric deviations caused by the adaptive process control. This deviation can be easily monitored by the real-time captured process data, but the key question will be how to react on deviations and how the decision-making process is designed.

4.3 Manufacturing complex approach angles

The potential of incremental point welding for onsite architectural fabrication would allow for the additive manufacturing process to be deployed beyond a factory environment and utilized directly onsite (e.g., for steel repair). The advantage is the relatively simple setup and easy accessibility to process components. To use the process in existing structures to add and connect separate pieces of steel, it is necessary to be able to create structures between existing elements.

In this setting, it is difficult to manufacture the connecting structure in a normal approach angle, one where the welder is facing straight down. To interconnect elements with incremental point welded structures, it is necessary to fabricate from both sides of the elements to be connected using a variety of approach angles to avoid collisions with the existing elements or the growing structure. This use case leverages the 6-axis system to realize the fabrication in more complex approach angles. For these angles, the computer vision has to be further adapted. As shown in the first experiments, the amount of added material as well as the parameters and the shielding gas cover will work slightly different depending on the angle of the weld.

The collision checking and questions of reachability will become more important and challenge the adaptive control on a number of different levels. Within this work, we demonstrated a number of advantages for the adaptive process control and introduced a first implementation for the creation of complex branch structure through incremental point welding. This research will be a basis for further investigations into large-scale manufacturing in steel construction.

References

Acheson R (1990) Automatic welding apparatus for weld build-up and method of achieving weld buildup; US patent no. 4,952,769

Biffi C, Tuissi A (2017) Industrial status on metal additive manufacturing. Metallurg Ital 109:5–10

Braumann J, Brell-Cokcan S (2012) Real-time robot simulation and control for architectural design. In: Proceedings of the 30th eCAADe conference, Prague, pp 479–486

Braumann J, Brell-Cockan S (2015) Adaptive robot control: new parametric workflows directly from design to KUKA robots. eCAADe 33:243–249

Colegrove PA, Martina F, Roy MJ, Szost BA, Terzi S, Williams SW, Withers PJ, Jarvis D (2014) High pressure interpass rolling of wire + arc additively manufactured titanium components. AMR 996:694–700

Cotteleer M, Joyce J (2014) Additive manufacturing paths to performance, innovation, and growth. Deloitte Rev 14:5–19

Coykendall J, Cotteleer M, Holdowsky J, Matho M (2014) 3D opportunity in a eurospace and defense: additive manufacturing takes flight. A Deloitte series on additive manufacturing. Deloltte University Press. https://www2.deloitte.com/content/dam/insights/us/articles/additive-manufacturing-3d-opportunity-in-aerospace/DUP_706-3D-Opportunity-Aerospace-Defense_MASTER2.pdf. Accessed 1 Dec 2019

Ding J, Colegrove P, Mehnen J, Ganguly S, Almeida P, Wang F, Williams S (2011) Thermomechanical analysis of Wire and Arc Additive Layer Manufacturing process on large multi-layer parts. Comput Mater Sci 50:3315–3322

Hong TS, Ghobakhloo M, Khaksar W (2014) Robotic welding technology. In: Comprehensive materials processing. Elsevier, Amsterdam, pp 77–99

Malladi A (2017) 3D metal printing technologies: a review. https://doi.org/10.13140/rg.2.2.26753.25448(Unpublished)

Mueller S, Im S, Gurevich S, Teibrich A, Pfisterer L, Guimbretière F, Baudisch P (2014) WirePrint. In: Adjunct publication of the 27th annual ACM symposium on user interface software and technology, October 5–8, 2014, Honolulu, HI, USA: Including] proceedings [and] companion/adjunct, Honolulu, Hawaii, USA, ACM, New York, NY, pp 273–280

Snooks R, Jahn G (2016) Closeness: on the relationship of multi-agent algorithms and robotic fabrication. In: Reinhardt D, Saunders R, Burry J (eds) Robotic fabrication in architecture, art and design 2016. Springer International Publishing, Cham, pp 218–229

Sutjipto S, Tish D, Paul G, Vidal-Calleja T, Schork T (2019) Towards visual feedback loops for robot-controlled additive manufacturing. In: Willmann J, Block P, Hutter M, Byrne K, Schork T (eds) Robotic fabrication in architecture, art and design 2018. Springer International Publishing, Cham, pp 85–97

Tedeschi A, Wirz F (2014) ADD—algorithms-aided design: parametric strategies using Grasshopper. Le Penseur publischer, Brienza, pp 297–301

Williams SW, Martina F, Addison AC, Ding J, Pardal G, Colegrove P (2016) Wire + arc additive manufacturing. Mater Sci Technol 32(7):641–647

Wu K, Kilian A (2019) Designing natural wood log structures with stochastic assembly and deep learning. In: Willmann J, Block P, Hutter M, Byrne K, Schork T (eds) Robotic fabrication in architecture, art and design 2018. Springer International Publishing, Cham, pp 16–30

Acknowledgements

Open Access funding provided by Projekt DEAL. The authors would like to thank the German Research Foundation DFG for the support of the research work that has been carried out within the framework of the Cluster of Excellence ‘Internet of Production’ (project ID: 390621612) and the participating partners from the industry for their support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Heimig, T., Kerber, E., Stumm, S. et al. Towards robotic steel construction through adaptive incremental point welding. Constr Robot 4, 49–60 (2020). https://doi.org/10.1007/s41693-019-00026-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41693-019-00026-4